Vapour blasting

WE VAPOUR BLAST ANY PARTS TO 'AS NEW' CONDITION

From bike parts – classic car parts. There’s no need to book for our vapour blasting service – just pop down with your parts and drop them off at reception.

The INS AND OUTS OF VAPOUR BLASTING

First and foremost we’re vapour blasting specialists in York with years of experience restoring all sorts of parts to as good as new.

Our machine (Wet Blaster or sometimes known as Vapour Blasting, Liquid Honing, Vapour Honing, Dustless Blasting or Slurry Blasting) uses a slurry mix of fine glass or white ally oxide combined with water, heat and compressed air all at once to gently but powerfully clean polish and hone parts.

The finish is amazing and we use it daily to key parts for the perfect preparation. It can also be used to clean & polish parts to a bright finish.

ThAT'S THE RAW TREATMENT

In the image below you can see the difference between steam cleaning and vapour blasting – the bottom half has been steam cleaned, whilst the top half has been vapour blasted. The results speak for themselves!

The main notable difference between dry blasting and vapor blasting is In dry blasting the abrasive impacts at an angle, leaving a deep anchor profile.

In wet blasting the water cushions the impact, meaning the surface profile is dispersed more evenly, in a feathered pattern. This allows for a finer blasting process.

Traditional dry blasting can cause frictional heat to the blasted surface. For softer metals this can cause unwanted warping. Wet blasting helps cool the frictional heat from abrasive blasting.

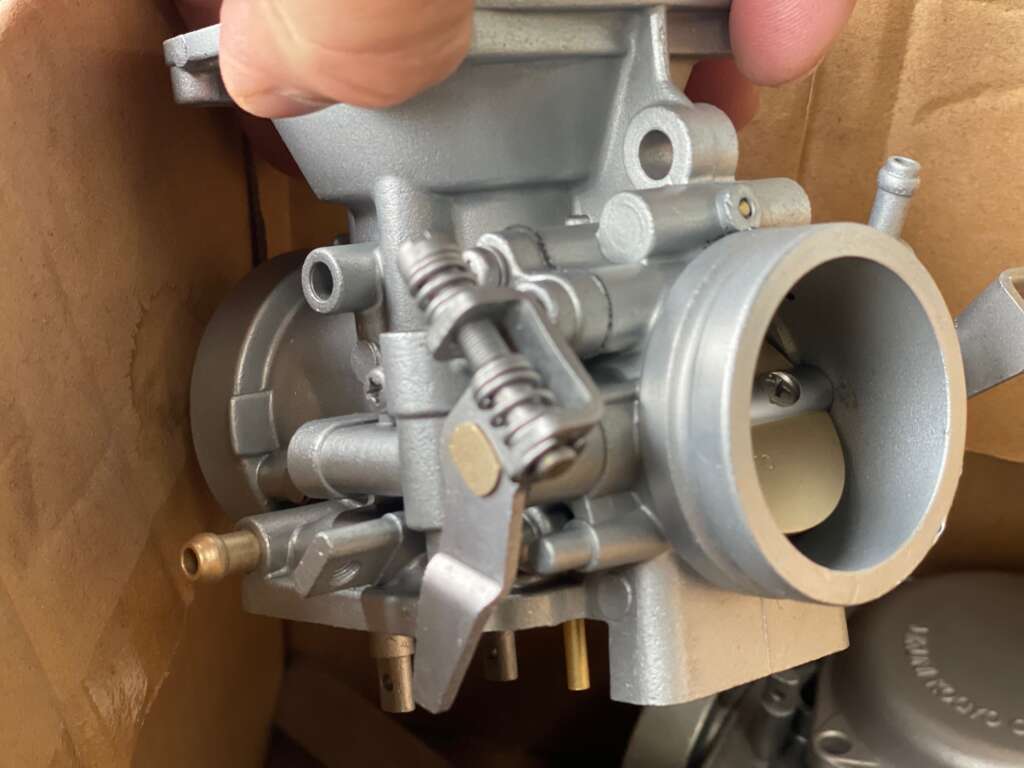

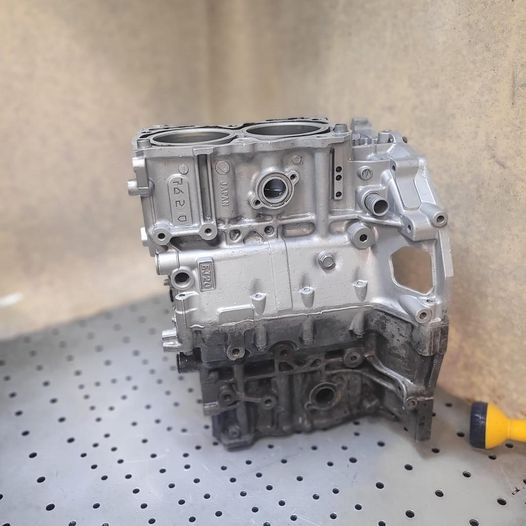

Vapour blasting is a natural choice for cleaning grease, rust, factory coatings, or other contaminants from old auto or motorcycle parts.

The cleaning and stripping process goes quickly with wet blasting, and the finish is much softer. Aluminium, chrome, or steel surfaces have a satin-like finish at the end of the process. There are certain jobs where traditional sandblasting is too destructive to the substrate to be practical. Because you wet blast with a lower PSI, and with softer media, there are times where that is more desirable. These include historical or antique restoration parts or carbs and engine parts for example.

WHY Choose RAW?

12 Months Warranty

Chemical Stripping

Original Manufacturers' Paints & Powder Coat Finishes

Oven Cured 2K Laquer / Oven Cured Powder Coat

REQUEST INFORMATION